BT holder and SK tool holder have significant differences in several aspects. Below is a detailed explanation of these differences.

BT Holder: BT is a Japanese standard, specifically a type of MAS BT (Japanese standard).

SK Tool Holder: SK is a German standard, typically categorized under DIN 69871 (German standard). However, there are also claims that the SK tool holder is a high-speed version of the BT holder.

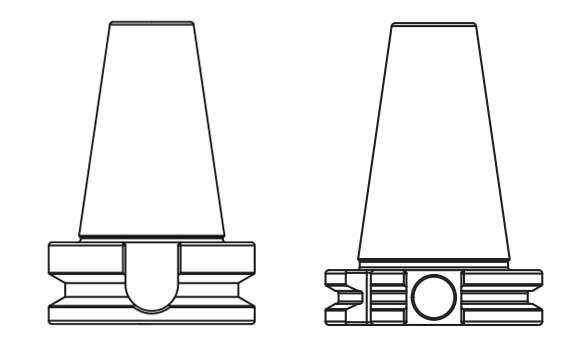

Flange: The flange thickness of the BT holder is relatively large, a design that enhances the holder's stability and rigidity during high-speed rotation. In contrast, the flange thickness of the SK tool holder is relatively smaller, but it still meets most machining requirements.

Keyway: Both keyways of the BT holder have the same depth and are not milled through. This design helps reduce vibrations and noise during cutting, improving clamping stability. On the other hand, the two keyways of the SK tool holder have different depths and are milled through, which increases the flexibility of its installation to some extent.

Taper: Both the BT holder and SK tool holder have a 7:24 taper, which is a structural commonality between the two. Therefore, when manually changing tools without the use of a robotic arm, the BT holder and SK tool holder are generally interchangeable, as long as the corresponding lathe is changed.

Positioning Method: Although the tapers are the same, there may be differences in the positioning methods of the two holders. The BT holder mainly relies on the accuracy of the taper surface and the spindle interface for positioning, whereas the SK tool holder may use a more complex positioning mechanism to ensure higher machining accuracy and stability.

BT Holder: Due to its thicker flange and locking mechanism, the BT holder typically offers higher clamping force and stability, making it suitable for heavy cutting and rough machining. However, when spindle speeds reach high levels (e.g., 40,000 RPM), the BT holder's end may experience significant deformation due to centrifugal force, causing radial runout to deteriorate. As a result, it is generally not used for high-speed cutting.

SK Tool Holder: The SK tool holder offers high rigidity and precision, making it ideal for high-speed, high-precision machining needs. Its design emphasizes stability and practicality, allowing it to maintain machining accuracy over extended periods. The high-speed performance of the SK tool holder makes it an ideal choice for high-speed cutting.