1) Turn on the power of the heat shrink machine to ensure that the machine is in normal working condition.

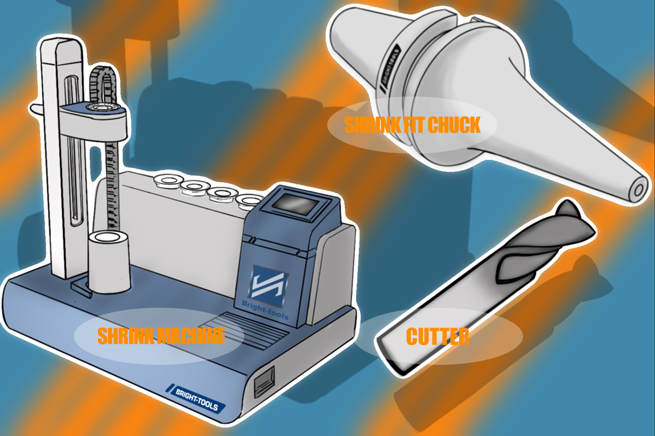

2) Set the hole diameter of the shrink fit holders to be heated on the heat shrinking machine, and adjust it according to the specification of the tool holder used.

3) Place the base, and place the tool holder on the base to ensure the stability of the tool holder during operation.

4) Carry out heating operation(Taking a tool holder with a hole diameter of 10 as an example, the heating time may only take about 3.2 seconds)

5) After the chuck has been heated, quickly insert the tools into the shrink fit tool holder. Take care to be steady when inserting the tools and make sure it is fully inserted into the handle.

6) Wait for the chuck to cool down (can be water-cooled, air-cooled or natural cooling), and wait for an appropriate cooling time to ensure the firm combination of the handle and the tool.

Once the holder has cooled completely, you can start machining the workpiece with the assembled shrink holder. Please make sure to operate safely and maintain correct cutting conditions and techniques during the work process.

1) Please be careful not to use high-speed steel tools, because the expansion coefficient of high-speed steel is similar to that of the chuck, which will make disassembly difficult. Carbide tools are required for assembly to ensure smooth operation.

2) Pay attention to safety when operating the heat shrinking machine, avoid touching the heating part, and avoid burns.

3) Depending on the specific model of heat shrinking machine, there may be different setting methods, please refer to the operation manual of the equipment.

4) When assembling the tool holder, please ensure that the set shrink hole diameter matches the tool used, so as to avoid excessive heating resulting in increased carbon deposits, reduced tool holder life, and insufficient heating resulting in the failure of the tool to be installed normally.

The above are the basic operation steps and precautions for installing a tool with a shrink fit tool holders. During the operation, please pay attention to safety and operate according to the instructions of the heat shrinking machine and tools. If there are other special requirements or details, please refer to the corresponding equipment instructions or consult a professional.

The Bright-tools is an enterprise focusing on high-end precision manufacturing, with 17 years of rich experience and profound technology accumulation.

With technological innovation and high-quality product service as the core, the company is committed to providing users with high-quality, cost-effective CNC tool holders, CNC accessories, tools, etc., and has been sold to 57 countries and regions, and is deeply trusted and praised by customers!

Bright-tools has the world's leading tool holders production base and inspection and testing center, and its manufacturing strength is in the forefront in China. Our core production and testing equipment include TAKISAWA, Doosan, HAIMER, Dieblod, ZEISS, ZOLLER, etc.

According this equipment further ensures our superior production efficiency and product quality.

We use advanced robotic automated production lines to ensure the stability of product quality and greatly improve production efficiency. At the same time, we use MES system, ERP system and OA office system to carry out comprehensive production management and enterprise resource planning, realizing the intelligentization of production and management, thus greatly improving the operation efficiency.

Bright-tools is one of the best cnc tool holder suppliers and manufacturers with lots of cnc tool holder types in China. The Bright-tools always adheres to the concept of "technology and quality", and is committed to providing customers with high-quality products and services. We look forward to working together with you to contribute our full strength and enthusiasm to the cause of intelligent manufacturing.