With the continuous development of industrial technology, the requirements for high-precision machining and high-speed machining are getting higher and higher. In this context, shrink-fit tool holders emerged as the times required. As a representative of high-precision tool holders, its working principle and advantages have gradually been widely recognized and applied.

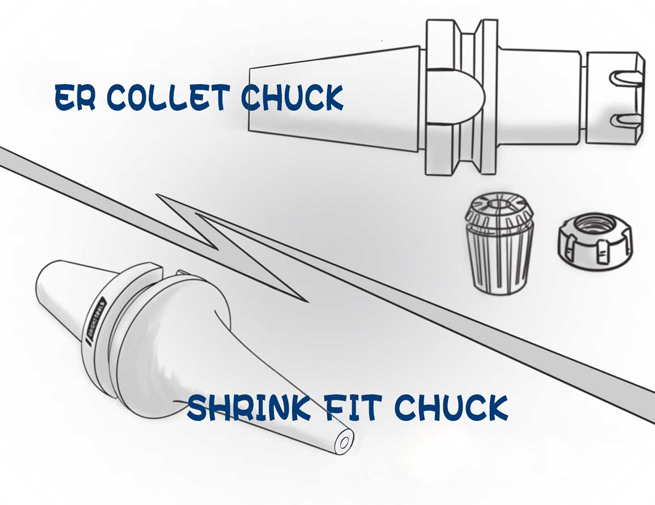

The shrink-fit tool holders offer unique advantages over traditional collet tool holders. The the shrink-fit tool holder adopts a one-piece design, which does not require additional pressure nut and collets to assist in clamping the tool. This simplified structure makes the tool holder high accuracy and more stable in dynamic balance.

So, how does the shrink-fit tool holder clamp and remove the tool?

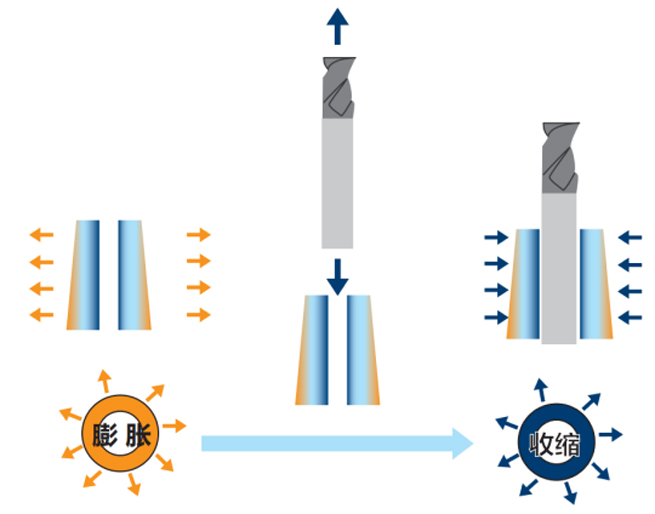

Its core is to use the difference in thermal expansion coefficient between the tool holder (heat-shrinkable die steel/special heat-shrinkable stainless steel) and the tool (tungsten carbide) to forcefully clamp and remove the tool.

Clamping: By using a special heat shrinking machine for heating, the inner hole of the tool holder will expand thermally under the action of heat, so that the tool can be smoothly put into the inner hole of the tool holder. When clamping, a large friction force is generated to ensure the transmission of large torque.

Disassembly: Use a special heat shrinking machine for heating, and the tool holder will expand thermally under the action of heat, while the expansion degree of the tool is relatively small. So that the tool can be easily removed from the inner hole of the chuck.

Due to its unique working principle, high precision, high stability and high efficiency, the shrink-fit tool holder has become the first choice in many industrial fields. With the further development of machining technology, it is believed that heat-shrink tool holders will have a broader application prospect and bring more convenience and benefits to industrial production.

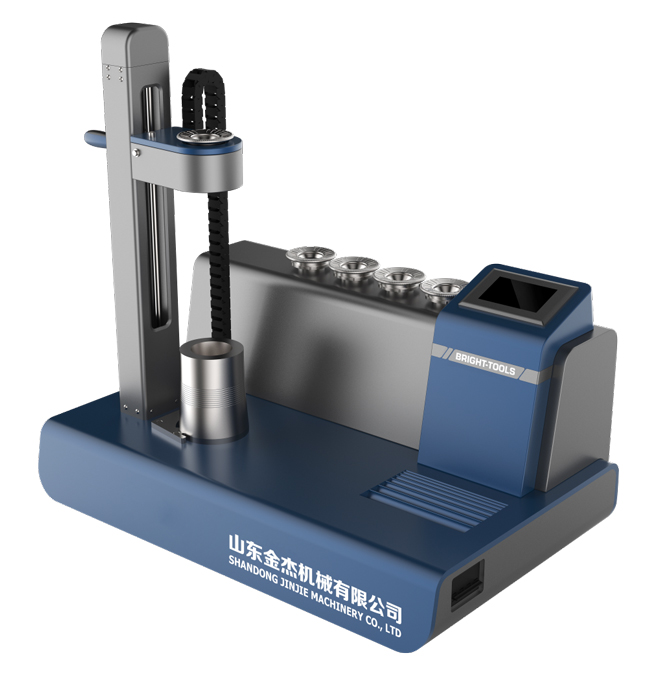

Bright-tools is an enterprise focusing on high-end precision manufacturing, with 17 years of rich experience and profound technology accumulation.

With technological innovation and high-quality product service as the core, the company is committed to providing users with high-quality, cost-effective CNC tool holders, CNC accessories, tools, etc., and has been sold to 57 countries and regions, and is deeply trusted and praised by customers!

Bright-tools has the world's leading tool holders production base and inspection and testing center, and its manufacturing strength is in the forefront in China. Our core production and testing equipment include TAKISAWA, Doosan, HAIMER, Dieblod, ZEISS, ZOLLER, etc.

This equipment further ensures our superior production efficiency and product quality.

We use advanced robotic automated production lines to ensure the stability of product quality and greatly improve production efficiency. At the same time, we use MES system, ERP system, and OA office system to carry out comprehensive production management and enterprise resource planning, realizing the intelligentization of production and management, thus greatly improving the operation efficiency.

Bright-tools always adheres to the concept of "technology and quality", and is committed to providing customers with high-quality products and services. We look forward to working together with you to contribute our full strength and enthusiasm to the cause of intelligent manufacturing.