Products | In-depth analysis of APU and CPU drill chuck tool holder

In the field of CNC machining, the choice of tool holders is like a strategic decision in a key battle, which directly affects the quality, efficiency and cost of machining. The APU tool holders and CPU tool holders introduced by BRIGHT-TOOLS CNC, each with its own distinctive features, provide diversified solutions for machining tasks with different needs.

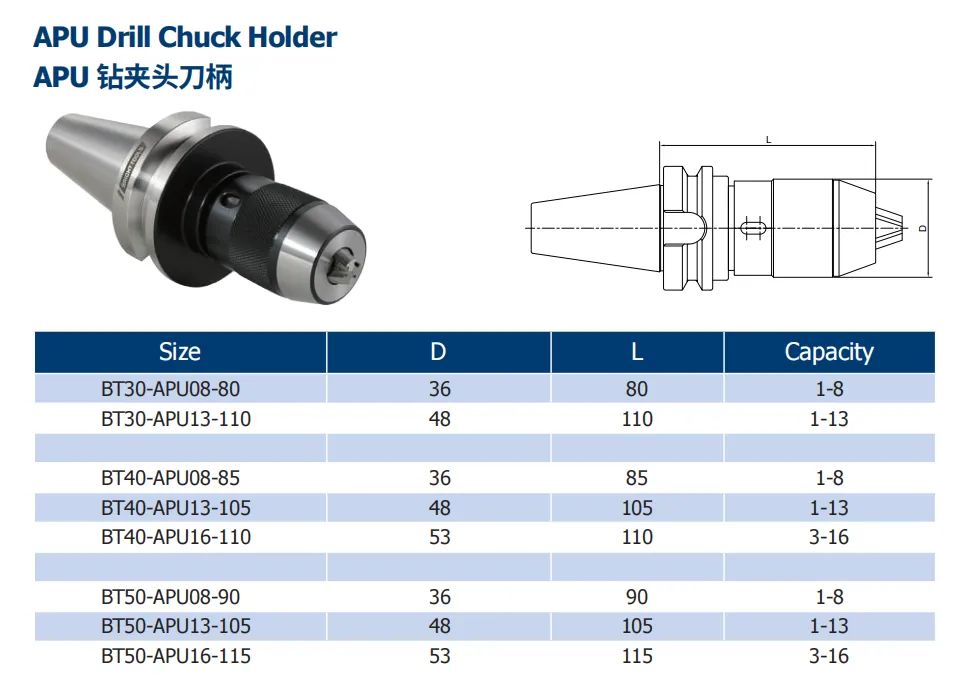

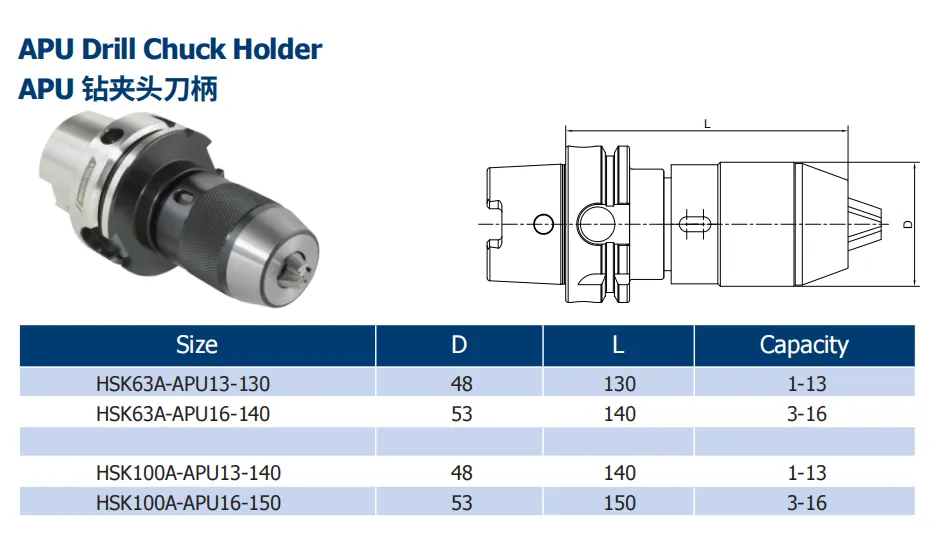

APU Tool Holders: convenient and practical machining tools

Products

The APU shanks are in the 8 - 12 silk range of accuracy, a level of precision that allows them to cope with a wide range of general machining requirements. This level of accuracy allows it to cope with a wide range of general machining requirements. It can be used consistently in scenarios such as general mechanical engineering and simple parts machining.

Application Scenarios

The main application scenarios are focused on the clamping of drills for routine drilling operations. Whether it's drilling sheet metal in a small machine shop or pre-drilling for simple assembly and manufacturing, the APU shanks can do it all.

Specificities

One of the significant features of APU tool holders is the ease of disassembly and reassembly. Frequent tool changes are common during machining processes, and the ease of disassembling and reassembling the APU shanks greatly reduces the time required for tool changes and improves machining efficiency. The operator can quickly load and unload the drill without the need for complicated tools or tedious steps, which is especially important in mass production or multi-process machining scenarios.

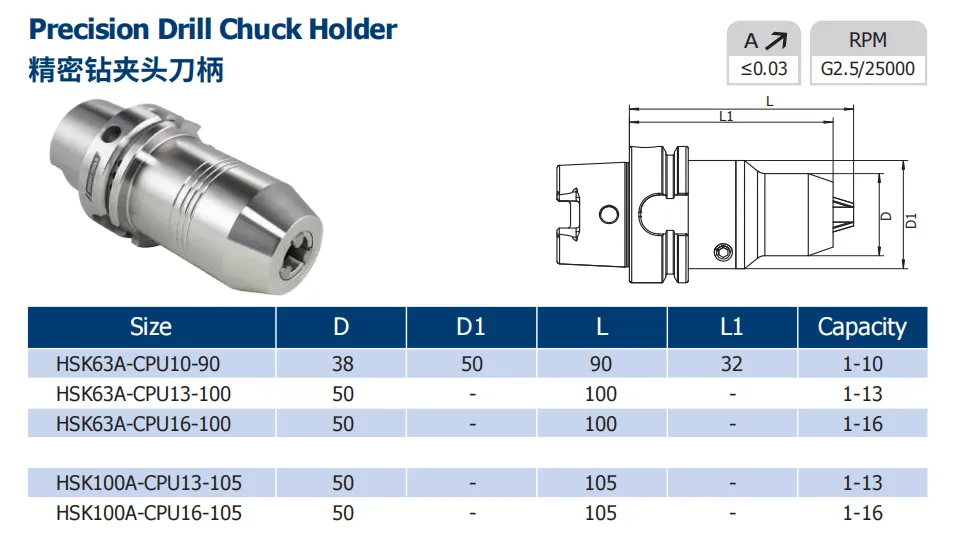

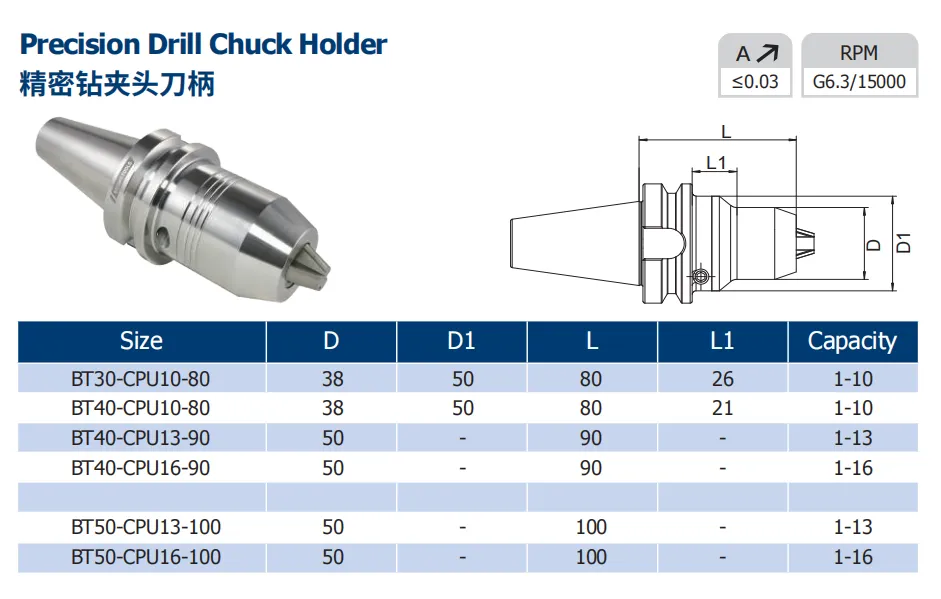

CPU toolholders: a model of high precision and stability

Description of the core structure

The CPU shank has a worm gear structure, and this unique structural design is the source of many of its outstanding performances. High precision control of the drill chuck is achieved by the precision transmission of the worm gear.

Application Scenarios

CPU shanks, which are also suitable for clamping drills, are used in applications that require the highest level of precision. In the field of high-end mould manufacturing, the precision of the smallest holes in the mould directly affects the mould's forming effect and service life, and the CPU shanks can also be used here to create high-quality mould products.

1. Superior Accuracy

CPU shanks with an accuracy of 3 - 5 filaments are nearly twice as accurate as APU shanks. This high precision is irreplaceable in precision machining.

2. Excellent Vibration Damping

CPU shanks have excellent vibration damping. During the machining process, the vibration generated by the machine tool will have a negative impact on the machining accuracy and tool life. The CPU shank can effectively absorb and disperse the vibration, providing a relatively stable working environment for the drill bit, making the machining surface smoother and flatter, and slowing down the wear of the tool, thus prolonging the service life of the tool and reducing machining costs.

Comprehensive Comparison of APU vs CPU Shanks

Price Dimension Considerations

In terms of price, APU tool holders have a clear advantage of being more affordable. For small businesses or start-ups with limited budgets and not particularly demanding machining accuracy requirements, APU tool holders are an economical and practical choice.

Vibration Damping Comparison

CPU shanks are far superior to APU shanks in terms of vibration damping, which ensures stability and precision in the machining process. APU shanks, on the other hand, are relatively weak in terms of vibration damping, which can lead to reduced machining accuracy and increased tool wear in the face of high vibration.

As mentioned earlier, the precision advantage of CPU shanks has made them a favourite in high-end machining. When machining products with extremely high requirements for dimensional and shape accuracy, CPU shanks are able to complete the task with precision, whereas APU shanks are not able to meet these stringent requirements with the same level of accuracy.

Locking force comparison

CPU tool holder have a strong locking force and excellent self-locking properties. In the machining process, especially when facing high hardness materials or large cutting forces, the strong locking force ensures that the drill bit is firmly fixed on the shank and will not be loosened or shifted. Its self-locking characteristics make it possible to maintain a stable clamping state even when subjected to large external forces. For example, when machining difficult-to-cut materials, this feature of the CPU tool holder effectively prevents the bit from slipping, ensuring smooth machining and improving tool life.

When choosing a drill chuck tool holder, companies need to consider their own processing needs, budget constraints and requirements for precision and stability and other factors. If it is a general machining task, focusing on cost control and ease of operation, the APU tool holder is a good choice; for those pursuing high precision, high stability, and more sensitive to vibration in the process of high-end machining projects, the CPU tool holder is undoubtedly a more ideal solution. Through the reasonable choice of APU or CPU tool holders, enterprises can achieve the best balance between machining quality and cost-effectiveness in the field of CNC machining, and enhance their market competitiveness.

Bright-tools is an enterprise focusing on high-end precision manufacturing, with 17 years of rich experience and profound technology accumulation.

With technological innovation and high-quality product service as the core, the company is committed to providing users with high-quality, cost-effective CNC tool holders, CNC accessories, tools, etc., and has been sold to 57 countries and regions, and is deeply trusted and praised by customers!

Bright-tools has the world's leading tool holders production base and inspection and testing center, and its manufacturing strength is in the forefront in China. Our core production and testing equipment include TAKISAWA, Doosan, HAIMER, Dieblod, ZEISS, ZOLLER, etc.

According this equipment further ensures our superior production efficiency and product quality.

We use advanced robotic automated production lines to ensure the stability of product quality and greatly improve production efficiency. At the same time, we use MES system, ERP system and OA office system to carry out comprehensive production management and enterprise resource planning, realizing the intelligentization of production and management, thus greatly improving the operation efficiency.

The Bright-tools always adheres to the concept of "technology and quality", and is committed to providing customers with high-quality products and services. We look forward to working together with you to contribute our full strength and enthusiasm to the cause of intelligent manufacturing.