The composition and structure of the tool system used in CNC turning processing are related to factors such as the type of machine tool holder, tool type, and whether the tool system requires power drive.

CNC lathes often use vertical or horizontal turret tool holders as tool magazines. The tool magazine has a capacity of 4 to 8 tools. They are generally arranged according to the machining process sequence and realize automatic tool change.

It is characterized by simple structure and fast tool change. A tool change only takes 1 to 2 seconds. It is generally not necessary to change the tool when processing parts with high similarity.

When processing different types of parts, it is necessary to reinstall the tool or replace the turret tool holder as a whole.

It consists of a machine tool holder (such as a turret tool holder), a tool holder base, a pre-adjustable quick-change tool holder, a pre-adjustable tool holder and a tool.

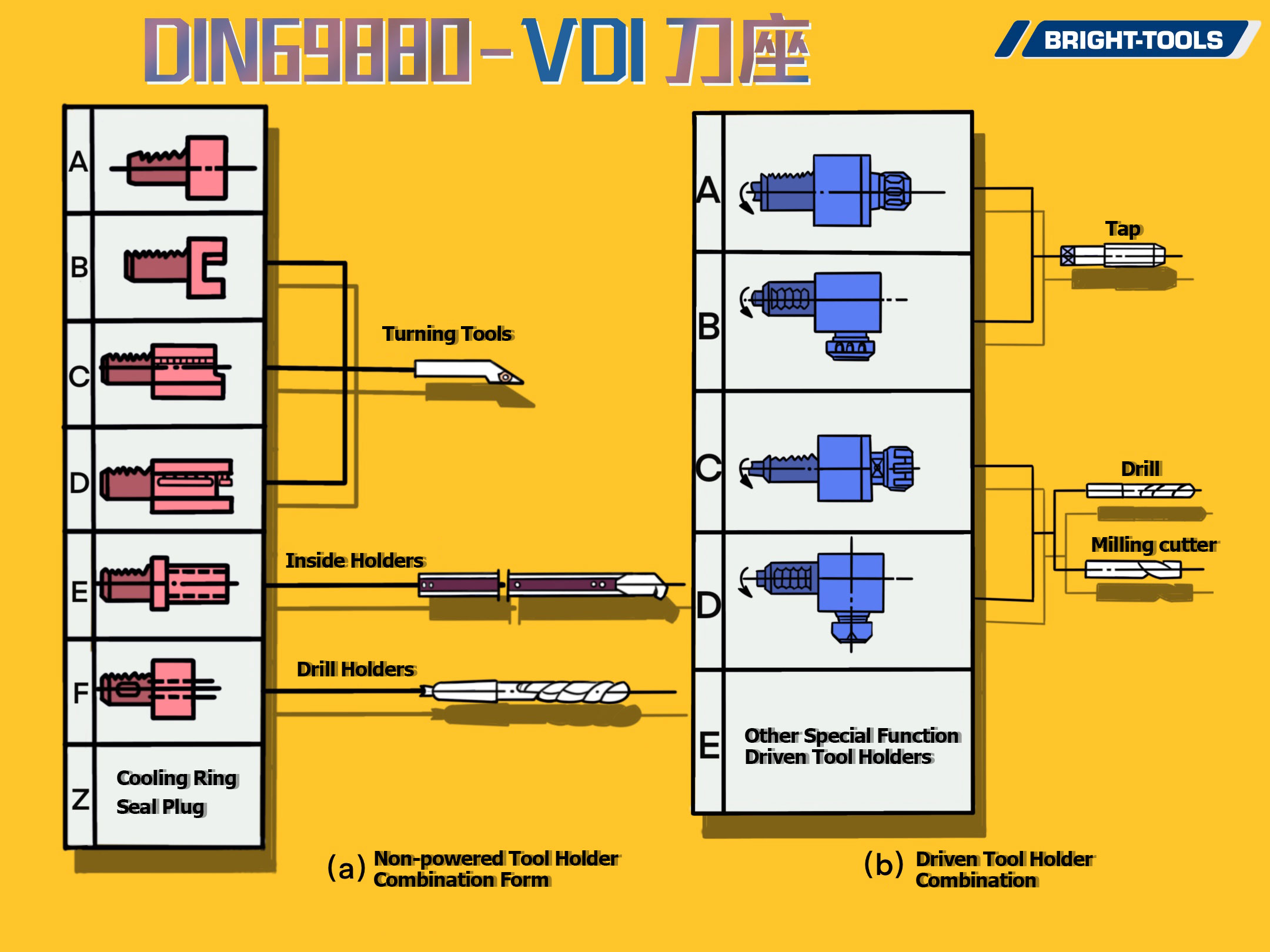

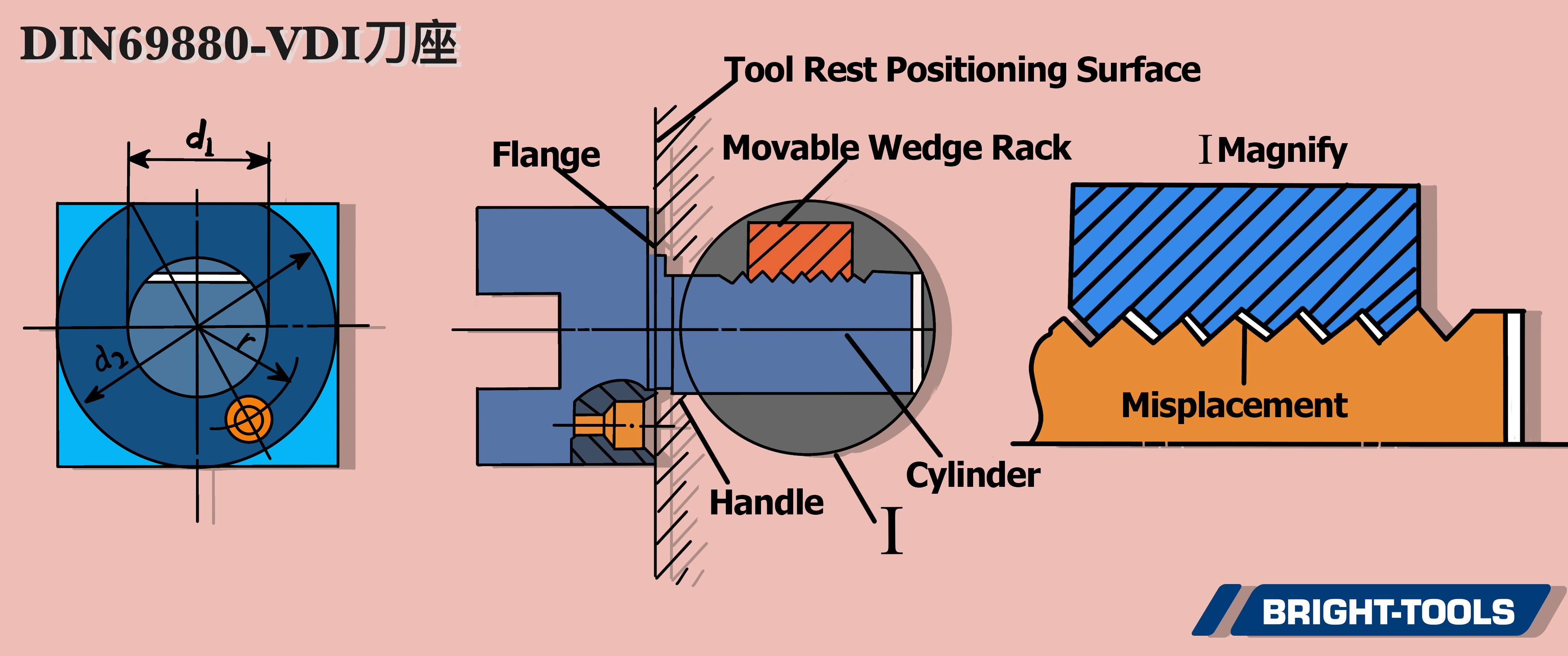

The German DIN69880 standard tool system (VDI tool holder) is divided into two types: fixed tool holder and powered tool holder. It has the characteristics of high repeatability positioning accuracy, good clamping rigidity, and strong interchangeability; it is suitable for end-face installation of lathe disc-shaped tool holders. In the case of knife hilt.

2. VDI tool holder type:

3. VDI handle connection diagram:

4. VDI product specifications:

Classified by handle: VDI:16/20/25/30/40/50/60

Classified by tool end:

Type B: transverse tool holder; Type C: longitudinal tool holder;----installs various turning tools.

Type E: equipped with various types of inner hole turning tools.

Type F: equipped with Morse drill bit.

Type Z: Install sealing plug.

.jpg)

5. Advantages of Jinjie VDI tool holders:

1) The VDI interface has undergone special heat treatment and high-precision grinding.

2) The VDI tool holder saves space and therefore facilitates the design of multi-tool holders.

3) Tool holder replacement is faster to reduce downtime.

4) Jinjie always stocks VDI products in batches, and the delivery speed is super fast! ! !

6. VDI production pictures of Jinjie workshop:

Bright-tools is an enterprise focusing on high-end precision manufacturing, with 17 years of rich experience and profound technology accumulation.

With technological innovation and high-quality product service as the core, the company is committed to providing users with high-quality, cost-effective CNC tool holders, CNC accessories, tools, etc., and has been sold to 57 countries and regions, and is deeply trusted and praised by customers!

Bright-tools has the world's leading tool holders production base and inspection and testing center, and its manufacturing strength is in the forefront in China. Our core production and testing equipment include TAKISAWA, Doosan, HAIMER, Dieblod, ZEISS, ZOLLER, etc.

According this equipment further ensures our superior production efficiency and product quality.

We use advanced robotic automated production lines to ensure the stability of product quality and greatly improve production efficiency. At the same time, we use MES system, ERP system and OA office system to carry out comprehensive production management and enterprise resource planning, realizing the intelligentization of production and management, thus greatly improving the operation efficiency.

The Bright-tools always adheres to the concept of "technology and quality", and is committed to providing customers with high-quality products and services. We look forward to working together with you to contribute our full strength and enthusiasm to the cause of intelligent manufacturing.